The Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) has been conducting research for more than a decade into aspects of alkaline water electrolysis (AEL) which are important for applications in practice. In addition to a high technology readiness level and good scalability to large performance classes, AEL is said to have high cost-cutting potential. This is because this technology does not require expensive precious metals like platinum or iridium where the availability of resources is a critical factor.

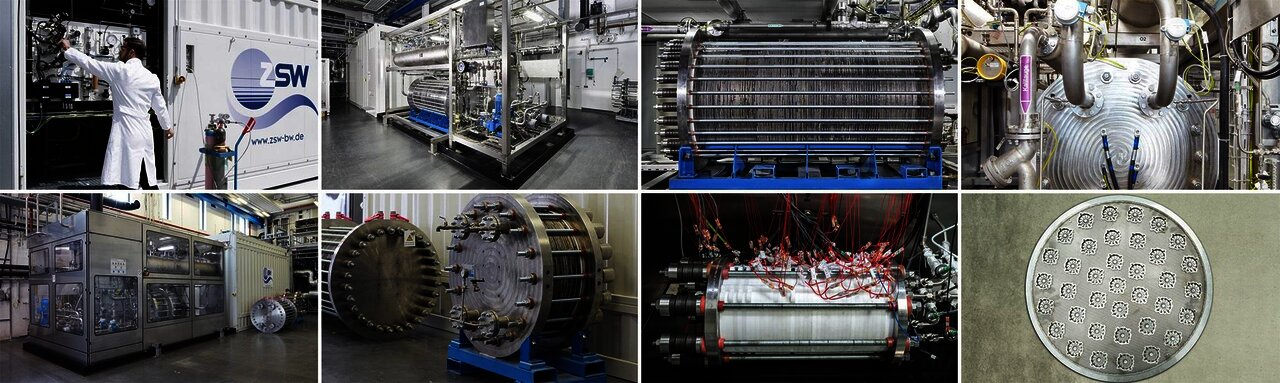

The ZSW focuses in its research and development work on the electrolysis system technology and also on the electrolysis stack with its core elements, such as cell frames, electrode packages and electrode coatings. In its capacity as the beating heart of an electrolyser, the electrolysis stack also has a major bearing on the efficiency and therefore the economic viability of hydrogen production.

The ZSW is focusing in its work on materials (e.g. electrode coatings), methods (e.g. manufacturing processes for components and electrolysis stacks) and process engineering concepts (e.g. design and construction of stacks, systems and test rigs) with a view to facilitating this move up to the multi-MW scale and allowing automated series production. The power range for electrolysers at the ZSW starts at a few kilowatts for research and test systems for the preliminary validation of materials and components and extends all the way to the lower megawatt scale for demonstration systems. Two proprietary CE-certified fully integrated systems in the 1 MWel power class have already been erected at the ZSW. Both non-pressurised systems and high-pressure electrolysers are being developed and built depending on the application or budget.

Quality control plays a major role in the development and prototyping of components right through to the construction of fully integrated systems. The ZSW is fully equipped with in-house test rigs and the necessary analytical tools for the comprehensive testing and measurement of electrolysis stacks and their components (electrodes, coatings, cell frames).

There are also alkaline non-pressurised and high-pressure electrolysis test rigs ranging in power from <1 kWel up to 500 kWel and up to 30 bar as well as material test facilities, e.g. for degradation tests.

Customers from industry have access to the laboratory infrastructure with its broad range of measurement apparatus and established methodology in order to test and validate their own developments, preliminary products and finished products (ElyLab test centre).